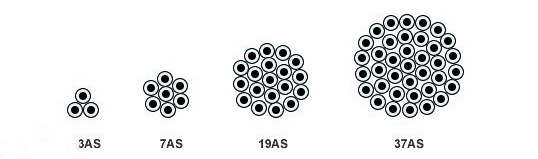

Galvanized steel wire strand , also called zinc coated steel wire, hop-dip steel wire can be supplied in single wire, three wire, seven wires , nineteen wires, thirty-seven wires. Its galvanized layer is bright and firm with strong corrosion-resistance, using hot dip galvanized vertical process, to ensure the thickness of zinc layer. As the core skeleton material of power cable, it directly serves the construction and renovation of power supply and power grid, and has the advantages of corrosion resistance, high strength, good elongation and high cost performance. Products are widely used in hanger, suspension, communication wire, overhead power line, cable steel core and fixed object tether, etc.

section structure: 1*3 wires, 1*7wires, 1*19wires, 1*37wires

| Wire diameter | Minimum Coating Mass (g/m2) | ||

| Class A | Class B | Class C | |

| 1.6 mm-1.90mm | 210 | 420 | 630 |

| 1.90mm-2.30mm | 220 | 440 | 660 |

| 2.30mm-2.70mm | 230 | 460 | 690 |

| 2.70mm-3.10mm | 240 | 480 | 720 |

| 3.10mm-3.50mm | 260 | 520 | 780 |

| 3.50mm-3.90mm | 270 | 540 | 810 |

Tensile strength for the galvanized steel wire is used to specify the breaking force of steel wire, can be divided into three levels.

| Wire diameter | Stress at 1% extension (Mpa) | |||

| Class A | Class B | Class C | Extra-High | |

| 1.6 mm-2.30 mm | 1310 | 1240 | 1170 | 1560 |

| 2.3 mm-3.05 mm | 1280 | 1210 | 1140 | 1560 |

| 3.05 mm-3.6 mm | 1240 | 1170 | 1100 | 1560 |

| 3.6 mm-4.8 mm | 1170 | 1100 | 1070 | 1560 |

| Wire diameter | Tensile strength (Mpa) | |||

| Class A | Class B | Class C | Extra-High | |

| 1.6 mm-2.30 mm | 1450 | 1380 | 1310 | 1770 |

| 2.3 mm-3.05 mm | 1410 | 1340 | 1280 | 1770 |

| 3.05 mm-3.6 mm | 1410 | 1340 | 1280 | 1770 |

| 3.60mm-4.80mm | 1380 | 1280 | 1240 | 1770 |

| Wire diameter | extension (%) | ||

| Class A | Class B | Class C | |

| 1.6 mm-2.30 mm | 3 | 3 | 3 |

| 2.3 mm-3.05 mm | 3.5 | 3 | 3 |

| 3.05 mm-3.6 mm | 4 | 3 | 3 |

| 3.60mm-4.80mm | 4 | 4 | 4 |

We have many kinds of steel raw material to choose from for the galvanized steel wire strand, and the steel material can be treated with lead hardening to achieve different strengths. The following table shows the chemical composition of steel .

|

Strength level |

% C |

% P |

% Mn |

% Si |

%S |

|

General |

0.45~0.50 |

0.032 |

0.5 ~1.00 |

0.10~0.34 |

0.041 |

|

High |

0.59~0.63 |

0.035 |

0.5 ~1.10 |

0.10~0.35 |

0.045 |

|

Extra-High |

0.65~0.83 |

0.035 |

0.5 ~1.10 |

0.10~0.35 |

0.045 |

Our company has passed ISO 9001 and ISO/TS 16949 quality management system certification, all the raw materials and semi-finished products for galvanized steel wire are tested and recorded. Every step from raw material to finished products can be traced.

Galvanized steel wire and strand—known for their corrosion resistance, durability, and tensile strength—are versatile materials widely used across industries. Below are their key applications, optimized for search visibility and user intent:

Galvanized steel wire strand is essential in construction for: Reinforcement: Strengthening concrete structures (e.g., bridges, buildings, foundations) as tie wires or rebar . Fencing & Safety Nets: Creating durable perimeter fences, temporary barriers, or fall-arrest systems on construction sites. Cable Structures: Supporting roofs, walkways, or cable-stayed bridges in architectural designs.

In agricultural settings, these materials excel in: Livestock Containment: Fabricating barbed wire fences, electric fencing, or livestock enclosures to secure animals. Crop Support: Training vines (e.g., in vineyards) or trellising crops like tomatoes using high-tensile galvanized wire. Irrigation Systems: Anchoring pipes, sprinklers, or drip irrigation lines.

For utility and communication networks: Power Transmission: Serving as overhead ground wires (earth strands) in electrical pylons to protect against lightning. Cable Support: Suspending telephone, internet, or TV cables (aerial bundling) between poles. Earthing Systems: Ensuring reliable grounding in electrical installations.

In harsh marine environments: Marine Ropework: Fabricating mooring lines, rigging, or anchor chains resistant to saltwater corrosion. Shipbuilding: Reinforcing hull structures or securing cargo on deck. Offshore Platforms: Supporting safety barriers, handrails, or equipment anchoring.

Industrial uses include: Conveyor Systems: Reinforcing belts or supporting heavy machinery components. Packaging & Binding: Strapping heavy goods (e.g., steel coils, wooden pallets) for transport. Mining: Creating support structures in tunnels or reinforcing safety barriers.

For homeowners and DIY enthusiasts: Gardening: Building plant supports, trellises, or wire mesh for compost bins. DIY Fencing: Installing temporary or decorative fences in backyards. Home Repairs: Securing gutters, roof anchors, or outdoor fixtures.

Adding value to your business is our ultimate goal. Please give us a call or leave us a message, our professional sales engineers will get in touch with shortly.